On-The-Fly Horizontal Boring and Dowel Insertion: How the OTF Was Developed

The engineering behind Pillar Machine’s continuous-feed horizontal boring and dowel insertion machine for cabinet and casework production.

By the Pillar Machine Engineering Team ⋅ 5-minute read

The OTF was intentionally engineered by the Pillar Engineering Team as an entry-level bore and dowel insertion machine. It is not designed to replace top-end, highly specialized systems. Instead, the OTF provides a practical entry point into horizontal boring and dowel insertion for shops that need real production capability without the footprint, cost, or complexity of premium equipment.

The result is not a stripped-down version of a high-end system. The OTF is intentionally positioned as an entry-level machine that is still capable of running in real production environments, shift after shift.

This positioning guided key engineering decisions, balancing performance with accessibility, integration, and long-term reliability.

OTF -1 Sample Part

Two identical parts are made with two operations on each part. One operation drills only holes, whilest the other also inserts dowels. The final assembly is nearly seamless.

Design Principles Behind the OTF

Production First. Every design decision was evaluated against how the machine would perform in an active cabinet shop, not a lab environment.

Approachable Automation. Controls, setup, and maintenance were engineered to be accessible for shops taking their first step into continuous-feed equipment.

Respect the Role of High-End Machines. The OTF is not intended to replace flagship, fully automated systems. It is meant to complement them or serve as a practical starting point.

What is On-The-Fly and Why It Matters

On-The-Fly is a coin termed by our Engineering Team for our belt-driven feed system paired with a drill and dowel insertion set-up. Instead of complex carriage assemblies and rail systems, we used our proven Larick belt system. Instead of moving the drill and dowel system to the part position, we simply advance the part to where it needs to be. What does this mean for production?

- Continuous part movement without stopping or repositioning

- Reduced handling and fewer opportunities for error

- More predictable cycle times

- Cleaner integration with upstream and downstream processes

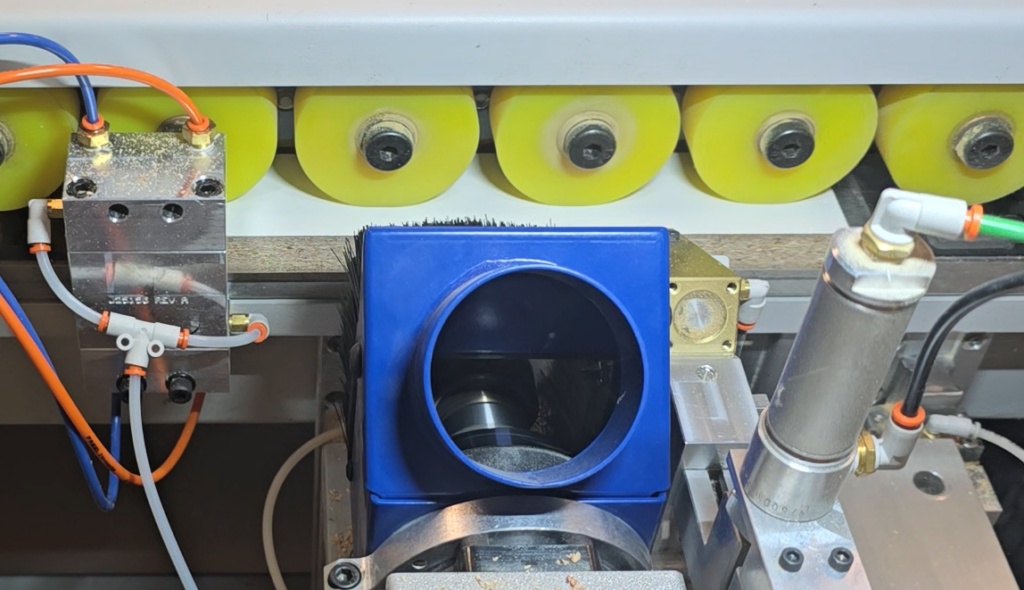

OTF-1 Bore and Dowel System

A closer look at the boring and dowel sytem on the OTF-1

Rather than chasing maximum speed, the OTF focuses on consistency and flow. For many shops, these factors have a greater impact on throughput and labor efficiency than raw cycle-time gains

While performance metrics matter, the true measure of the OTF is how it supports day-to-day production. Feedback from real-world use has consistently focused on workflow stability and reduced operator intervention.

Engineering an Entry-Level Machine for Production Use

Entry-level does not mean experimental. The OTF was engineered using the same internal standards applied across both the Pillar and Larick product line. Mechanical assemblies, motion control, and software architecture were selected to balance cost with long-term reliability.

This approach allows the OTF to operate alongside higher-end machines in mixed production environments, supporting growing shops without forcing premature investment in fully automated systems.

From Production to Delivery: Installing the OTF in a Working Shop

Installing the OTF in a customer’s shop was treated as an extension of development, not the finish line. Pillar Machine supported delivery, positioning, alignment, and startup to ensure the machine integrated into the customer’s existing workflow.

As expected with new, complex equipment, early operation revealed opportunities for refinement. Our engineering and service teams remained involved after installation to address these items quickly and permanently.

This commissioning phase helped validate design decisions under real production conditions and ensured the OTF met both internal and external expectations.