5000

Series Sander

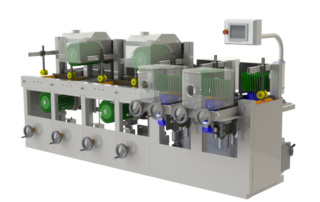

The 5000 Series machine can be configured to sand the top, bottom or sides of parts utilizing a chain driven roller feed system. It has a fixed height roller conveyor.

More Machines Like This

Operator interface: Manual Control

Standard machine configuration includes: Two top heads

Conveyor width: 15 inch

Material thickness: Up to 6″ thick

Feed Rate: 4 to 47 FPM

Direction of travel through machine: “Right to Left” standard.

Dust Collection Ports: Multiple 4-5″

Dust Collection CFM: 800+

208-240 Volt, 3 Phase, 50-60 Hertz

Spindle dimensions:

1 1/4″ diameter

Spindle HP:

1 HP (higher HP is available, see option section of this quote for more details)

Spindle RPM:

Top head: 200 to 900 RPM

1. Abrasives not included. Ask your sales rep for recommended abrasives to include with this machine.

Length & Weight is dependent on configuration.

Larick 5000 Series Description

The 5000 Series is designed with a small footprint, is rugged, dependable, and manufactured with as many ‘off the shelf’ parts as possible to minimize downtime and maintenance.

Standard Operation

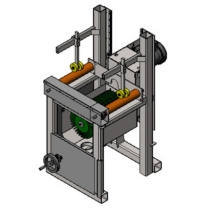

The top and bottom spindles are belt driven with full power down to 450 RPM. Side heads may be direct drive with horizontal, vertical and tilt adjustments, or belt driven for increased torque. Speed and direction are controlled from the touchscreen. Each motor’s load is also displayed.

Pillar Machine will build the 5000 series machine to fit your needs for width, height, and number of Top, Bottom or Side Heads.

Inverters control the feed rate, spindle speed, and rotational direction. Larger diameter sanding and wire brushes deliver best results. Top and bottom spindles are belt driven for increased torque. Side heads may have tilt and vertical adjustment with direct drive motors, or be belt driven to increase torque.

What the 5000 Does

5000 Series Machines are typically used to perform the following operations:

brush or wire sanding

simultaneously sanding on top, bottom, and sides

5000 Series Machines:

accepts sanding and/or wire brushes that are up to 11″ diameter

Touchscreen Interface

5000 Series Sander uses a touchscreen to to control speed and direction. Each motor load is also displayed.

What Comes with the Larick 5000

Larick 5000 Infeed

Larick 5000 Outfeed

Installation Requirements

Factory installation is not necessary for this machine. It will arrive fully assembled and ready for production once necessary power and air are connected to it.

Phone support for startup is offered on this machine at no charge.

Factory on-site installations are available if preferred. Contact your Pillar Machine representative if interested in obtaining a quote for this option.

Made In The USA

All Larick Machines are built 100% at our Fort Collins, Colorado Factory.

The benefits of purchasing an American made machine extend far beyond simply supporting the “local” economy.

Additional benefits include:

- All parts are sourced from vendors in North America.

- Parts availability is increased and assures honest pricing.

- Real Factory Support.

When technical assistance is required you can often talk directly to the people that built, wired, and tested your machine.

1 Year Warranty

Larick Profile Shaping & Sanding, a Pillar Machine company, warrants to the original purchaser of the Larick Machinery that this product will be free from defects in material or workmanship, when purchased, and under proper, normal use, for one (1) year from the original date of delivery. Original purchaser understands that the machine warranty is only applicable to machines that are or were paid in full within 60 days of the original delivery date.

The full defined warranty can be found here: https://pillarmachine.com/pillar-service/#warranty

Options for the Larick 5000

Shown here is an example of a 5000 machine with two top heads and two sets of side heads and a 10’8″ wide footprint.

This picture is for representation purposes only showing the machine with multiple options that are not included as standard features.

Larick 5000 Series Sander Extra Top Head Option

This extra top head option adds one top head station on the 5000 Series Sander.

The head is adjustable up and down via hand wheel on the front

of the machine with a digital readout.

Spindle dimensions:

1 1/4″ diameter

Spindle HP:

1 HP (higher HP is available, see option section of this quote for

more details)

Spindle RPM:

Top head: 200 to 900 RPM

Notes:

1. This option will make the machine approximately 22 inches longer for each set of side heads you add.

2. Sanding abrasives are not included with this option.

Larick 5000 Series Sander Extra Bottom Head Option

This extra bottom head option adds one bottom head station on the 5000 Series Sander.

The head is adjustable up and down via hand wheel on the front of the machine with a digital readout.

Spindle dimensions:

1 1/4″ diameter

Spindle HP:

1 HP (higher HP is available, see option section of this quote for more details)

Spindle RPM:

Top head: 200 to 900 RPM

Notes:

1. This option will make the machine approximately 22 inches longer for each set of side heads you add.

2. Sanding abrasives are not included with this option.

Larick 5000 Series Sander Side Heads Option

This side heads option adds two (one set) side heads on the 5000 Series Sander.

The heads can tilt side to side and/or in or out.

Option includes:

2 each 1 HP sanding spindles. 150 to 900 RPM

Notes:

1. This option will make the machine approximately 22 inches longer for each set of side heads you add.

2. Sanding abrasives are not included with this option.

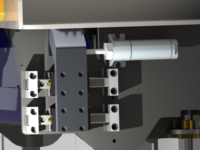

Larick 5000 Top or Bottom Jump Cylinder

This jump cylinder option will add a “Jump Cylinder” to either a top head or bottom head station. This option allows you to make the choice to not sand in this particular station.

Using a switch for this station will move the top or bottom head away from the part by 1″. This allows you to maintain your sanding setup for parts you want to sand while quickly moving the sanding heads out of the way on parts you don’t want to sand.

Notes:

1. This option is for one station only. If your machines configuration has more than one top or bottom heads, this option will need to be selected for each station you want to have this feature.

Larick 5000 Side Jump Cylinder

This jump cylinder option will add “Jump Cylinders” to both side heads and allows you to make the choice to not sand in this particular station. Using a switch for this station will move the side heads away from the part by 1″ each head. This allows you to maintain your sanding setup for parts you want to sand while quickly moving the sanding heads out of the way on parts you don’t want to sand.

Notes:

1. This option is for one station only. If your machines configuration has more than one set of side heads, this option will need to be selected for each set of side heads.

Larick, A Pillar Machine Company | 2HP Motor Upgrade

This 2HP option upgrades the standard 1 HP motor to a 2 HP

Note:

1. This option is for use on a top or bottom head station.

2. The price listed for this upgrade is for the upgrading of one motor.

Larick, A Pillar Machine Company | 3HP Motor Upgrade

This option upgrades the standard 2 HP motor to a 3 HP

Notes:

1. The price listed for this upgrade is for the upgrading on one motor.

2. Only top heads on the 700 series can be upgraded.

Larick, A Pillar Machine Company | 5HP Motor Upgrade

This option upgrades the standard 2 HP motor to a 5 HP

Notes:

1. The price listed for this upgrade is for the upgrading on one motor.

Larick 10HP Motor Upgrade

10 HP Spindle option upgrades the standard 2 HP motor to a 10 HP

Note: The price listed for this upgrade is for the upgrading on one motor.

Larick 460 Volt 3 Phase Option

460 volt three phase option is cost is per spindle.

Larick 575 Volt 3 Phase Option

575 volt three phase option is price per spindle.