OTF

Horizontal Bore & Dowel Insertion Machine

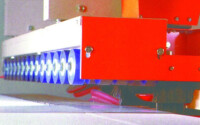

The OTF is a horizontal belt advance bore and dowel insertion machining center.

It is designed to belt position the workpiece, bore a hole, then advance the workpiece to the correct location for the inserter, inject glue or water (for pre glued dowels), and fire the dowel into the hole. A part is placed into the work zone referencing the back fence and advancing the part onto the belt. The belt system allows constant part feeding into the machine.

More Machines Like This

PartPart Width: minimum 4.5″, unlimited maximum

1/2″ minimum to 2″ maximum thickness capability

X Axis – Belt driven

Y & Z Axis – Manual by use of hand digital readout

Y – Axis Guides: 6” wide feed chain with four staggered rows of hold down tires and Larick Fence

Z – Axis Guides: Front adjusting handwheels with digital readouts

Compressed Air – 90-110 PSI at 20 CFM

Dust collection port – 1 each 2.5″ port at 350 CFM

Depth – 48″

Height – 74″

Weight 13150 lbs. appx

OTF Machine Description

Our dowel insertion machine is a horizontal point to point machining center designed for boring, gluing, and doweling.

The OTF bore and dowel machine is designed to belt position the workpiece to the drill, then belt position to the dowel inserter, inject glue or water (for pre-glued dowels), and insert the dowel into the hole, providing a cycle time of less than 1 second for each bore, glue and dowel insertion when the holes are spaced at 64 mm intervals.

Standard Operation

A part is placed into the work zone referencing the back fence. The workpiece is then fed into the belt and roller system to be processed. The belt allows continuous feeding of parts.

What the OTF Does

The OTF is typically used to perform the following operations:

Horizontal Boring

Glue Insertion

Dowel Insertion

Touchscreen Interface

A 15″ Industrial Color Touchscreen is used to write and store programs.

The 15″ touch screen monitor makes viewing the specific parameters of a program easy.

Note: Image may not necessarily depict final Operator Interface and is only used as an example of an Operator Interface Screen.

OPERATOR INTERFACE SCREEN

The on-screen graphics of the operator interface have been designed to allow for quick programming at the machine. Typically, programs can be written and recalled in less than one minute. The Interface is open architecture allowing it to integrate with design software that can give hole locations in the form of a .xml file or a bar code (with bar code reader purchase found in options).

Standard Features in the software include:

1. Graphic interface to show where holes are to be drilled and if a dowel is to be inserted.

2. Parametric Programming.

3. Pattern Drilling/Inserting.

4. Password protection of certain features/functions.

5. Online diagnostic capability (if machine is connected to an internet connection).

6. Toggle between Metric or Imperial programing parameters.

Note: Image may not necessarily depict final Operator Interface and is only used as an example of an Operator Interface Screen.

Pillar Machine Maintenance Screen

OTF MAINTENANCE SCREEN

A Maintenance Screen gives you the ability to manage inputs, outputs and machine offsets.

From this screen you can manually trigger all outputs as well as visually see if the machine is seeing the inputs correctly. You also set the machine parameters that are not as communally used such as fence and spindle offsets from this screen.

Because this screen is password protected you can be selective with who you grant access to it.

Industrial Computer (Windows 10)

SPECIFICATIONS:

Video: on board

Ethernet 1 x PCIE Broadcom GbE (or similar)

USB: 2 x USB 2.0 (or similar)

Serial Port: 1 x RS-232 (or similar)

100-240 VAC External Power adapter (or similar)

Windows 10 operating system

Note: photo may not represent the exact computer to be used in the machine.

What Comes with the OTF

-

Larick Fence

Larick Conveyor System

Pillar OTF Carriage Mounting

Pillar Machine Dowel Inserter

Pillar OTF Vibratory Dowel Bowl

Pillar Machine Glue/Water Injection System

Pillar Machine High-Frequency Spindle

Pillar Machine Parametric Programming

Installation & Training

Factory installation is not necessary for this machine. It will arrive fully assembled and ready for production once necessary power and air are connected to it.

Phone support for startup is offered on this machine at no charge.

Factory on-site installations are available if preferred. Contact your Pillar Machine representative if interested in obtaining a quote for this option.

Made In The USA

All Pillar Machine Machines are built 100% at our Salt Lake City Factory.

The benefits of purchasing an American made machine extend far beyond simply supporting the “local” economy.

Additional benefits include:

- All parts are sourced from vendors in North America.

- Parts availability is increased and assures honest pricing.

- Real Factory Support.

When technical assistance is required you can often talk directly to the people that built, wired, and tested your machine.

1 Year Warranty

Pillar Machine warrants to the original purchaser of the Pillar Machine Machinery that this product will be free from defects in material or workmanship, when purchased, and under proper, normal use, for one (1) year from the original date of delivery. Original purchaser understands that the machine warranty is only applicable to machines that are or were paid in full within 60 days of the original delivery date.

The full defined warranty can be found here: https://pillarmachine.com/pillar-service/#warranty

Options for the OTF

Pillar Machine Glue Pump for System

Glue pump system adds a diaphragm pump to the glue system. This allows the system to work with glue. The pump has a maximum air pressure of 100 psi, and is a 1:1 pressure ratio.

Note: Glue Pump system will inject glue or water with equal effectiveness. When using glue Pillar recommends using: “Franklin Assembly 161” Glue (or similar but not to exceed 160 centipoise of viscosity); when using water Pillar recommends using “Distilled Water”. Franklin Assembly 161 can be purchased from Pillar Service.

Pillar Machine 18″ Dowel Bowl

This upgrade changes the machine from having a 12″ Vibratory dowel bowl to a 18″ diameter bowl.

The bowl can hold up to 3,000 8 mm dowels at a time.

Notes:

1. Selecting this option may increase your machines lead time.

2. Photo may not represent the exact dowel bowl to be used in the machine.

Pillar Machine Fixed Mounted Barcode Reader

Fixed mounted Barcode Reader option allows the operator to scan barcodes at the machine as a means of opening a part file. This will open a file that has the exact name in the program folder.

Notes:

1. Barcode reader only opens files that are meant to be read and used on this specific type of machine.

2. Option includes one standalone fixed mounted barcode reader and all required software to use it.

3. Photo may not represent the exact barcode reader to be used in this option.

4. Selecting this option may increase your machines lead time.

This option adds rear guarding to the machine with hinged access doors. The doors are made of tube steel and expanded metal.

Notes:

1. This option is a welded feature installed during manufacturing.

2. Selecting this option may increase your machines lead time.

3. This option does not include an electronic interlock.

4. This option guards the machines sides and back. The top will remain open.